RELATED NEWS

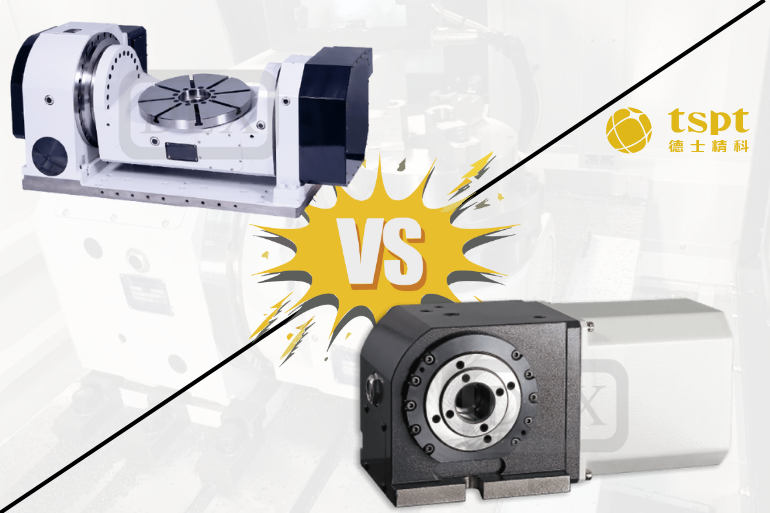

4th Axis vs. 5th Axis Rotary Tables – Choosing the Right CNC Rotary Table for Your Machining Needs

4th Axis and 5th Axis Rotary Tables in CNC Machining

In CNC machining, adding a rotary table can transform a standard three-axis machine into a more versatile production tool. By introducing additional rotational movement, these tables enable multi-sided machining, reduce setup times, and allow the production of more complex part geometries. A 4th Axis Rotary Tables 4th-axis rotary table provides a single additional rotation, ideal for indexing and machining multiple faces without manual repositioning. In contrast, a 5th-axis rotary table adds two rotational axes, enabling simultaneous multi-axis control for intricate surfaces, undercuts, and high-precision contouring.

tspt 4th Axis CNC Rotary Tables – High-Precision Indexing for Multi-Sided Machining

Functionality

tspt’s 4 Axis Rotary Table and CNC Tilting Rotary Table products add an additional rotational axis (A or B) to a 3-axis CNC machine, enabling precise indexing or continuous rotation. This capability enables the simultaneous machining of multiple sides of a workpiece, eliminating the need for manual repositioning and significantly reducing setup times, thereby enhancing workflow efficiency.

Key Benefits

- Zero Backlash Positioning – Utilizes Roller Cam Gear technology for precise, repeatable accuracy even under heavy cutting loads.

- High Rigidity Bearings – Supports stable operation at high speeds and heavy-duty cutting.

- Compact Footprint – Maximizes machining envelope while integrating seamlessly into existing CNC setups.

- Long-Term Reliability – Patented cam profiles reduce wear and extend service life.

Applications

- Multi-sided machining of prismatic components.

- Gear cutting, bolt pattern drilling, and cylindrical surface engraving.

- Turbine blade indexing and other rotational part machining.

- Widely used in aerospace, automotive, mold-making, and medical industries.

Explore tspt 4 Axis Rotary Tables →

tspt 5th Axis CNC Rotary Tables – Complex Geometry Machining with Maximum Precision

Functionality

A 5-axis CNC rotary table from tspt adds two rotational axes—typically A and C—enabling the workpiece to be rotated and tilted simultaneously. This capability allows complex parts with curved surfaces, deep cavities, and undercuts to be machined in a single setup, reducing both cycle time and the risk of dimensional errors caused by multiple clamping operations.

Key Benefits

- Dual-Axis Motion – Supports 5-sided machining and simultaneous multi-axis contouring.

- High Accuracy, Low Backlash – Roller Cam Gear and precision bearings ensure smooth, repeatable positioning.

- Versatile Machining – Suitable for sculpted surfaces, precision molds, and aerospace-grade parts.

- Built for Durability – Engineered for long-term, high-performance operation in demanding production environments.

Applications

- Aerospace: turbine blades, impellers, and blisks.

- Automotive: engine blocks, cylinder heads, mold cores.

- Medical: orthopedic implants, surgical instruments.

- Complex general engineering requiring compound angle machining.

Explore tspt 5 Axis CNC Rotary Tables →

Comparing tspt 4th Axis vs. 5th Axis Rotary Tables

| Feature | tspt 4th Axis Rotary Table | tspt 5th Axis Rotary Table |

| Rotational Axes | 1 (A or B) | 2 (A & C or A & B) |

| Complexity | Moderate, easier to program | Higher, requires advanced CAM programming |

| Setup Efficiency | High – fewer setups for multi-side machining | Maximum – single setup for highly complex parts |

| Machining Capability | Indexing & simple contouring | Complex freeform surfaces & undercuts |

| Ideal Applications | Prismatic parts, gears, bolt patterns | Aerospace blades, molds, medical implants |

| Cost | More affordable | Higher investment, greater versatility |

<

Why Choose tspt Among CNC Rotary Table Manufacturers

As one of the leading CNC Rotary Table Manufacturers, tspt offers:

Proven Roller Cam Gear Technology – Ensures zero-backlash precision for stable, high-quality machining.

Custom Configurations – Multiple sizes, clamping systems, and motor options to match specific CNC setups.

Industry Experience – Trusted by aerospace, automotive, and high-precision engineering sectors worldwide.

Full Technical Support – From installation guidance to maintenance training.

Conclusion: Choosing Between a 4-Axis Rotary Table and a 5-Axis CNC Rotary Table

Choosing between a 4-axis rotary table and a 5-axis CNC rotary table depends on the complexity of your parts, precision requirements, and production goals. For efficient, multi-sided machining with simplified setups, a 4-axis solution may be sufficient. However, for intricate geometries, reduced cycle times, and maximum flexibility, a 5-axis setup is often the best investment.

Ready to upgrade your CNC machining capabilities? Contact tspt today to discuss the right rotary table solution for your production needs. Whether you require the efficiency of a 4-axis rotary table or the advanced precision of a 5-axis CNC Rotary Table, our engineering team can provide tailored recommendations, technical support, and competitive solutions to help you achieve improved productivity and accuracy.

ABOUT US

Over four decades we have accumulated a vast experience in the design and production of mechanical devices, producing well-received customized cams, automatic tool changers, and intermittent indexing drives for automation applications.

NEWS CATEGORIES