Comparison of Transmission Methods of Different Rotary Tables

| Type | Advantages of DEX’s Roller-Type Transmission | Worm Drive Transmission |

|---|---|---|

|

|

|

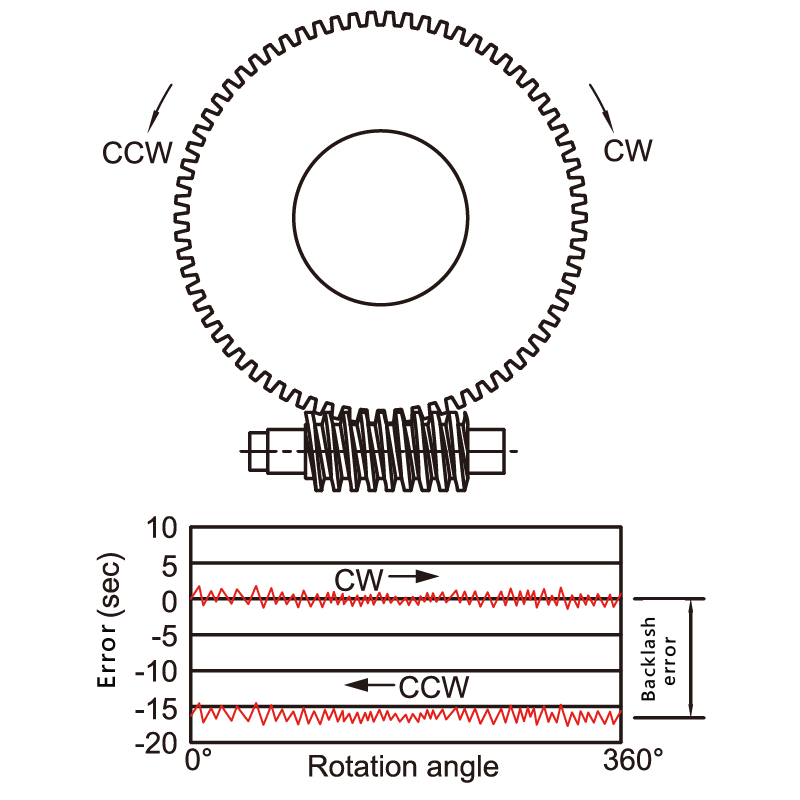

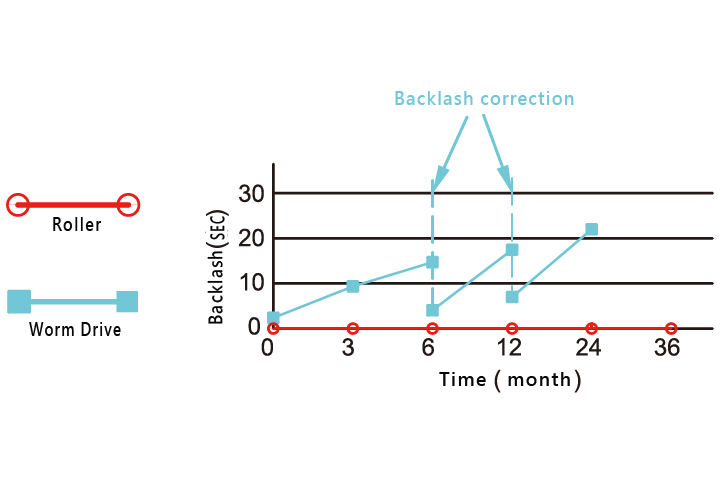

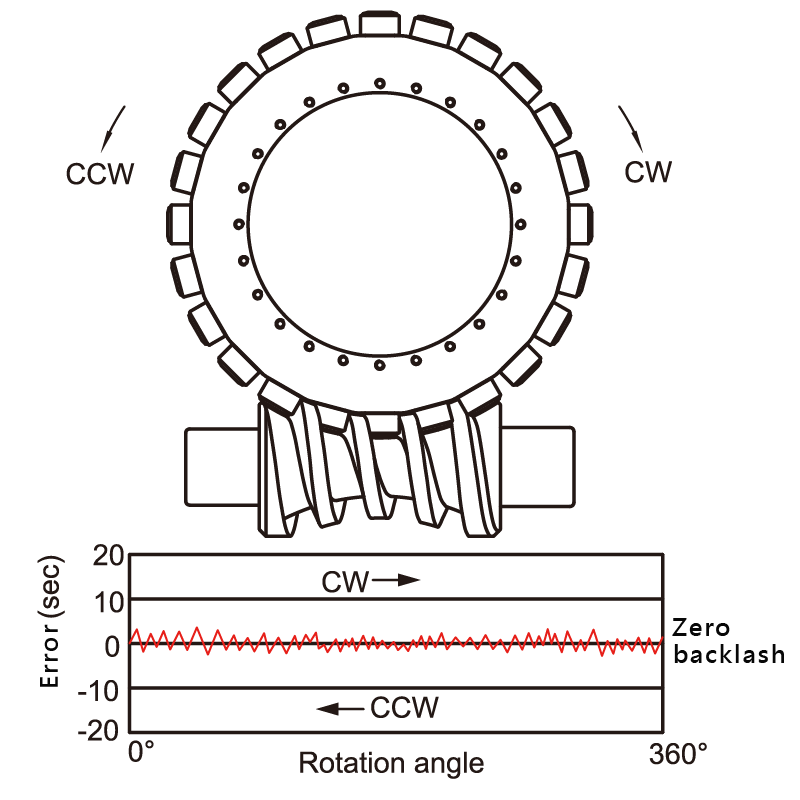

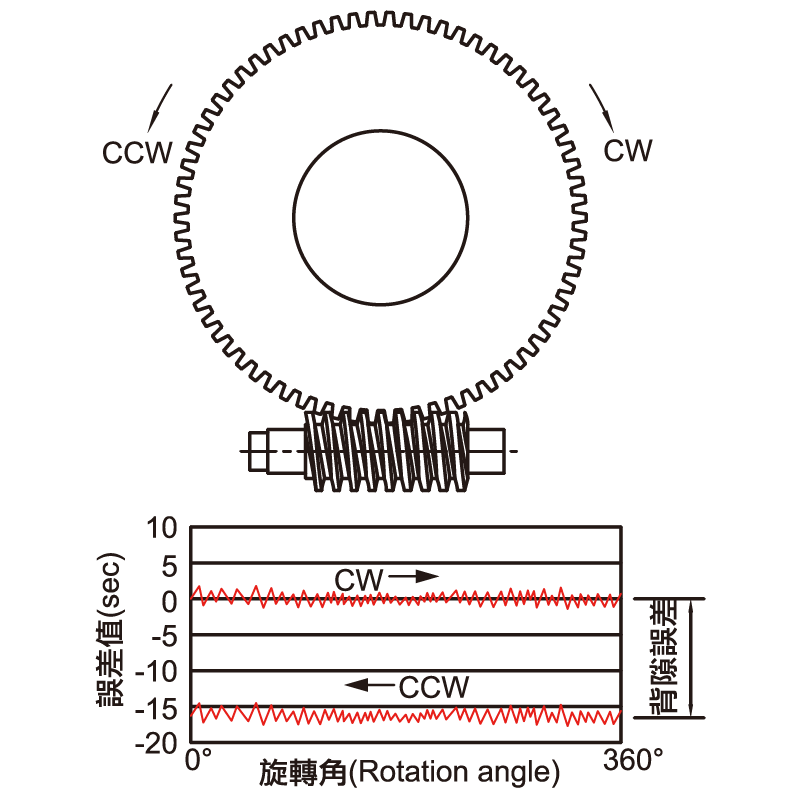

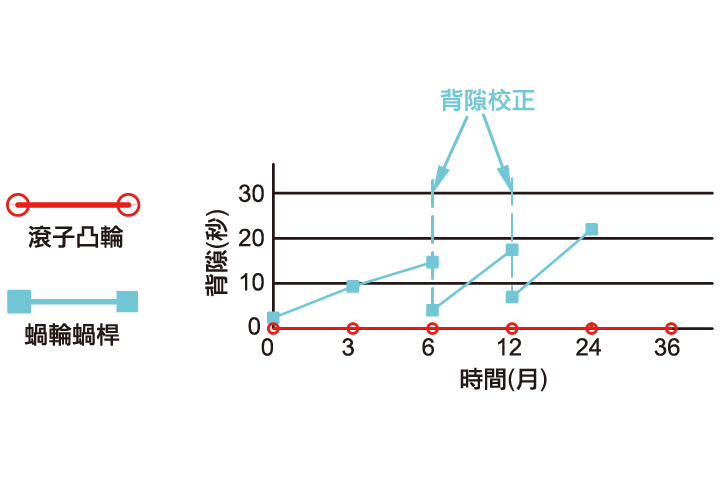

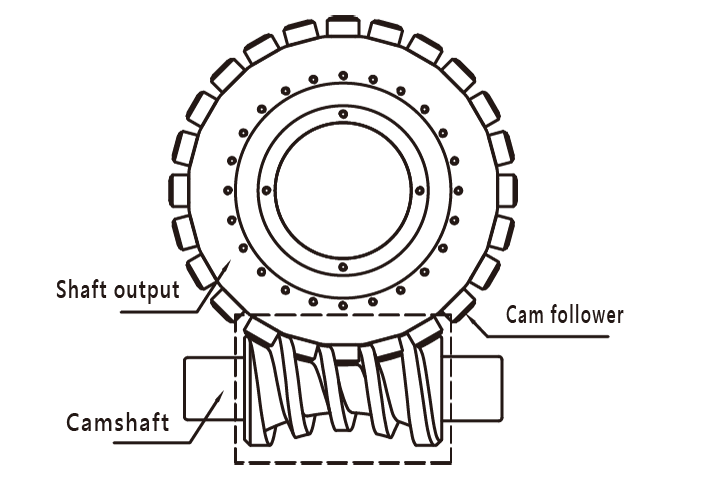

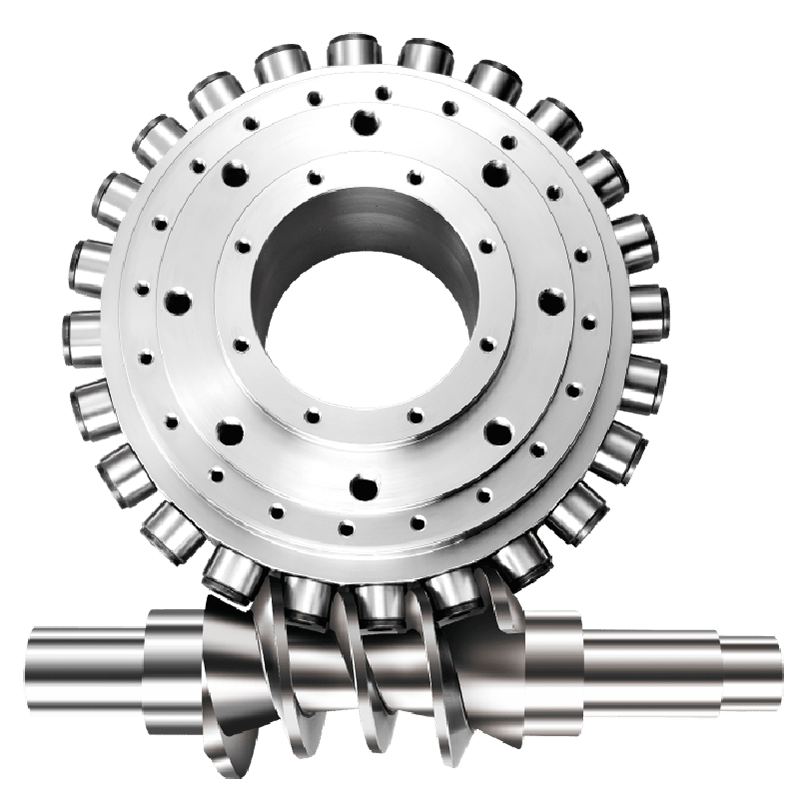

| Zero backlash | Rolling contact between the roller and the cam, no positive reversal backlash problem, greatly improving the ultra-precision characteristics of the roller cam, reducing the defect rate and improving the quality, which is a breakthrough for precision machining technology. | Friction extrusion conduction, worm gear easy to wear and short life. |

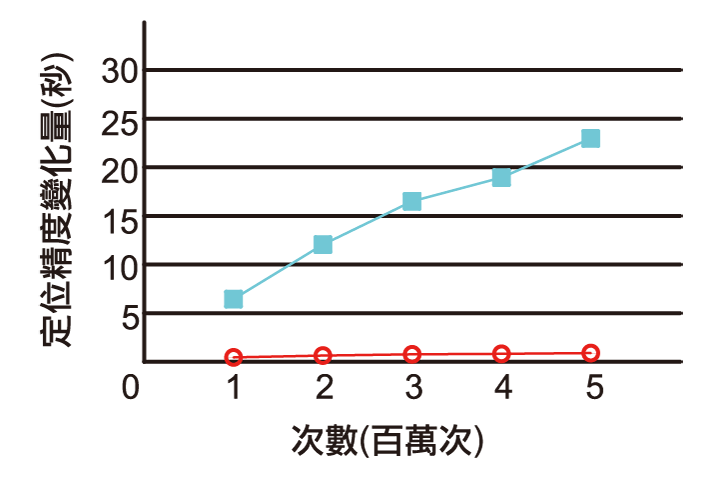

| Ultra-high efficiency conduction | Roller cam type turret conducts in rolling mode, reduces wear, high transmission efficiency, high speed operation, and conduction efficiency of over 90%. | Conduction efficiency 50~60%. |

| Prepressing | Yes | No |

| Maintenance-free | Due to low wear and low aging, it can maintain initial accuracy for a long time. | For the high-precision machining, the reverse direction will produce backlash, which will affect the processing quality. |

| Thermal displacement | Even at high speeds, reduce friction, reduce thermal displacement, improve quality stability, and reduce non-performing rates. | Accuracy reliability is not easy to maintain. |

| Braking performance | When the brake is positioned, the disc surface will not sway back and forth, and the positioning brake will remain within 2µm, which can highly demonstrate the precision machining quality. | Even if the optical scale is added, only the positioning accuracy can be solved, but when the backlash error is large, the vibration frequency during processing is high. (The surface roughness is poor), the optical ruler compensation compensates for the vibration frequency during processing and the wear of the tool is higher than roller cam type. |

Long Life |

Positioning Accuracy |

|

|

|

|

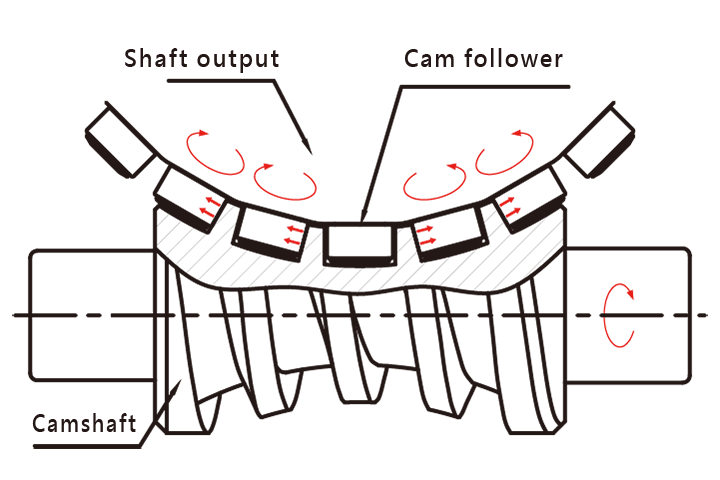

CAM

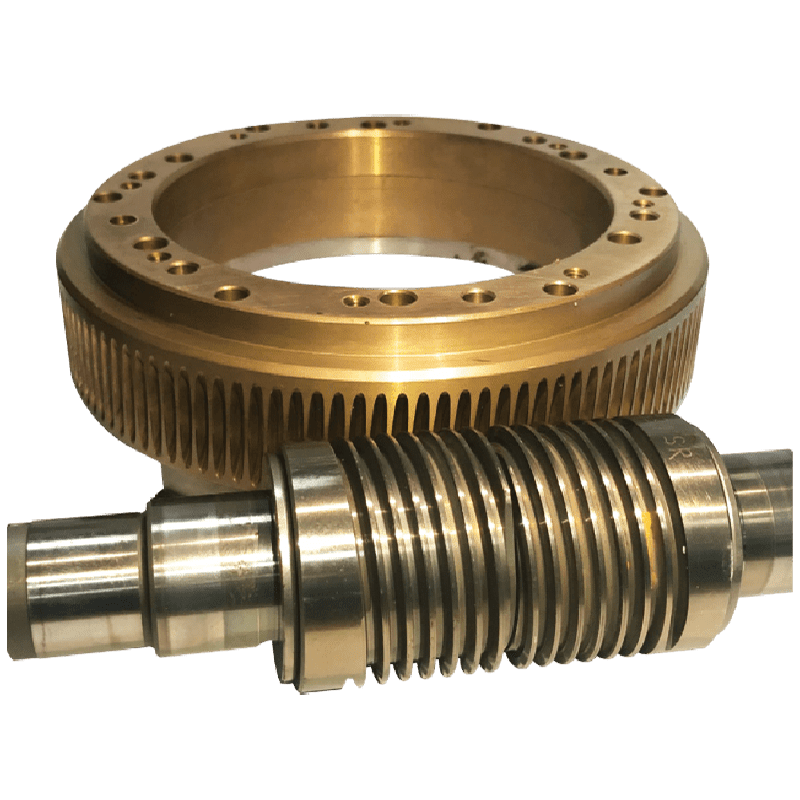

Roller-Type Transmission

Conduction efficiency 90~95%